SOLUTIONS

PUMPING SOLUTIONS

Sanitary Centrifugal Pumps:

- Cast/Forged to Min Wall Thickness of 6mm

- Over 30 Years Service Life

- Simple Design Easy to Maintain Low NPSH Requirements

- High Efficiency

- Low Noise Emissions

Sanitary Positive Displacement Pumps:

- Hygienic, fully CIP-able rotary lobe pump

- Handles products with viscosities of up to 1,000,000 cPs

- Able Achieve Differential Pressure up to 34.5 bar

- Large Pump Range

- High Efficiency – Small Clearance

- Gentle Product Handling

Sanitary Progressive Cavity Pump:

- The progressive cavity pump is a positive displacement pump with one single rotating shaft.

- A stainless steel rotor and a rubber stator

- Renowned for their versatility,

- Models are available in a choice of AISI 304, 316 stainless steel or in cast iron.

- Flow rates up to 130 m3/h, pressures up to 24 bar and temperatures up to 100 °C.

- Can handle almost any kind of fluid up to 800.000 cps., including abrasive liquids and suspensions with solids.

- The pumping action is delicate, without sudden pulsation

- The flow rate is proportional to the rotational speed.

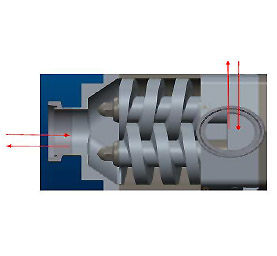

Sanitary Twin Screw Pump:

- Positive displacement pumps with a twin screw.

- Gentle handling of the product due to the shape of the rotor and the working without any product slip and dead zone.

- No foaming.

- High flexibility for wide products and duties.

- Very high efficiency.

- Excellent suction capability.

- Constant performance even with products having a range of viscosities.

- Differential pressure up to 25bar (max30bar).